PRODUCT

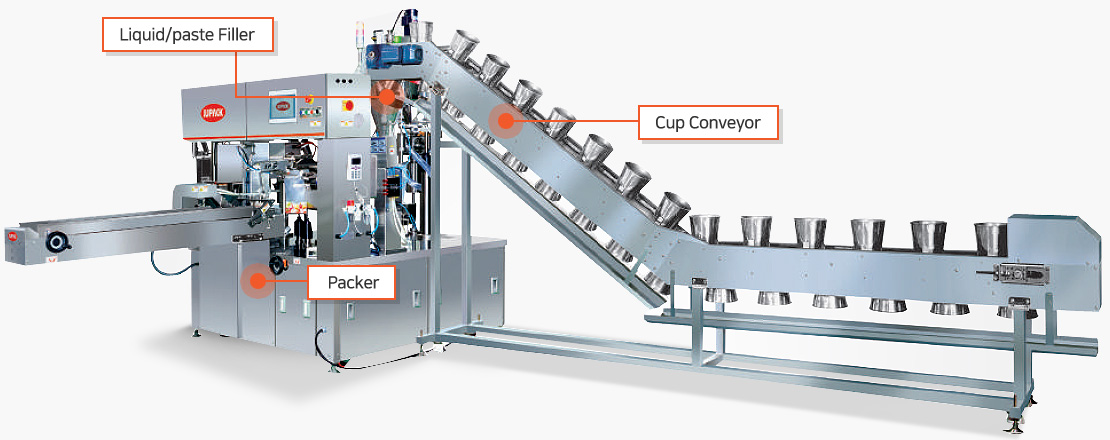

Liquid-Paste packer For Liquid, Paste, Gel, Lump product

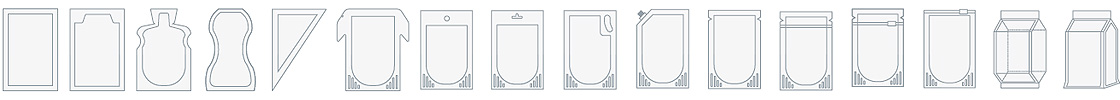

Available pouch type

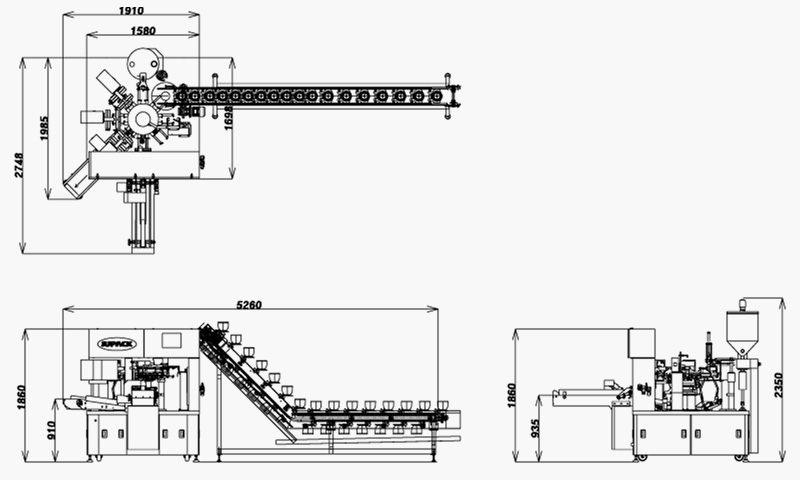

Model & Specification

| Model | JR-6S2540 | JR-7D1024 | JR-8S1024 | JR-8S1530 | JR-8D0915 | JR-8D1024 | JR-10S1024 | JG-8S0815 | JG-8S1520 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Speed (Pouches / min) |

10 ~ 30 | 30 ~ 80 | 30 ~ 50 | 30 ~ 50 | 60 ~ 100 | 60 ~ 100 | 30 ~ 50 | 20 ~ 30 | 20 ~ 30 | |

| Production speed depends on product, pouch type / size and filling volume | ||||||||||

| Pouch size range (mm) |

Width | 250 ~ 400 | 100 ~ 240 | 100 ~ 240 | 150 ~ 300 | 100 ~ 150 | 100 ~ 240 | 100 ~ 240 | 80 ~ 150 | 150 ~ 200 |

| Length | 250 ~ 470 | 100 ~ 400 | 100 ~ 400 | 130 ~ 470 | 100 ~ 400 | 100 ~ 400 | 100 ~ 400 | 100 ~ 400 | 100 ~ 400 | |

Advantage of Jupack machine

-

01

Synchro piston filler – Optimized filling performance as machine speed

-

02

Simply & Sanitary design – Ease cleaning & maintenance / assemble-disassemble design

-

03

Flat, Stand-up, Zipper, Corner Spout pouch available.>

-

04

Recipes record and recall function – Easy format changeable.

-

05

Simply & Sanitary design – Ease cleaning & maintenance / assemble-disassemble design

-

06

Electrical cabinet located above filling and cleaning zone

-

07

Easy pouch size change via a touch screen or a handle within 5 minutes

-

08

Special designed pouch feeding conveyor for stacking many pouches and no jams of pouches

-

09

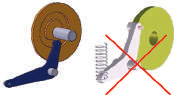

Captured CAM driven train, No spring

-

10

Sanitary cylindrical pouch grippers, no exposed spring

-

11

Individual four grippers design, no center gripper which has much errors

-

12

Hot-fill , Steam flushing, CIP and other accessries are available.

-

13

Wash-down design(IP65)

Products

-

01

Sauces, Juices, Soup, Jelly, Ketchup, Jam, Soy-sauce, Edible oil, Fruit extract

-

02

Liquid detergent, Shampoo, Rinse, Liquid soap, Softner